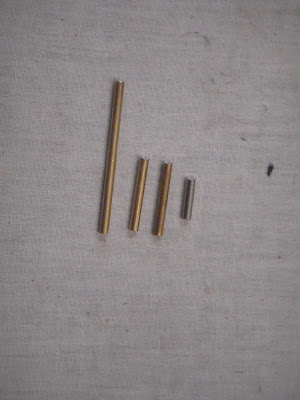

Next we faced both ends of all the pieces and filed a groove into the three smaller pieces so that they could sit flush on the longer one.

After all the filing was done, it was time to go over to the soldering station and clamp the long bit and one of the legs into place, coat the joint with flux and heat the area up into the solder flows into place.

To finish the other two legs, you just repeat the steps for the first one until you have an F...

and then finally an E.At this point the E looks really nasty so we cleaned it up by dropping it in the pickle (phosphorus acid) and letting it sit in there until it's cleaner than before. The next step is to remove any excess solder with a file and later sand paper. Also, if there are any nicks and imperfections in the metal, those need to be removed before you can buff. After all the filing and sanding, you take it over to the buffing machine and go until it's mirror-like.

No comments:

Post a Comment